APPLICATIONS:

Welding ye9% Cr-1% Mo masimbi uye 9% Cr - 2% Mo masimbi anoshandiswa kumagetsi emagetsi uye high pressure mudziyo.

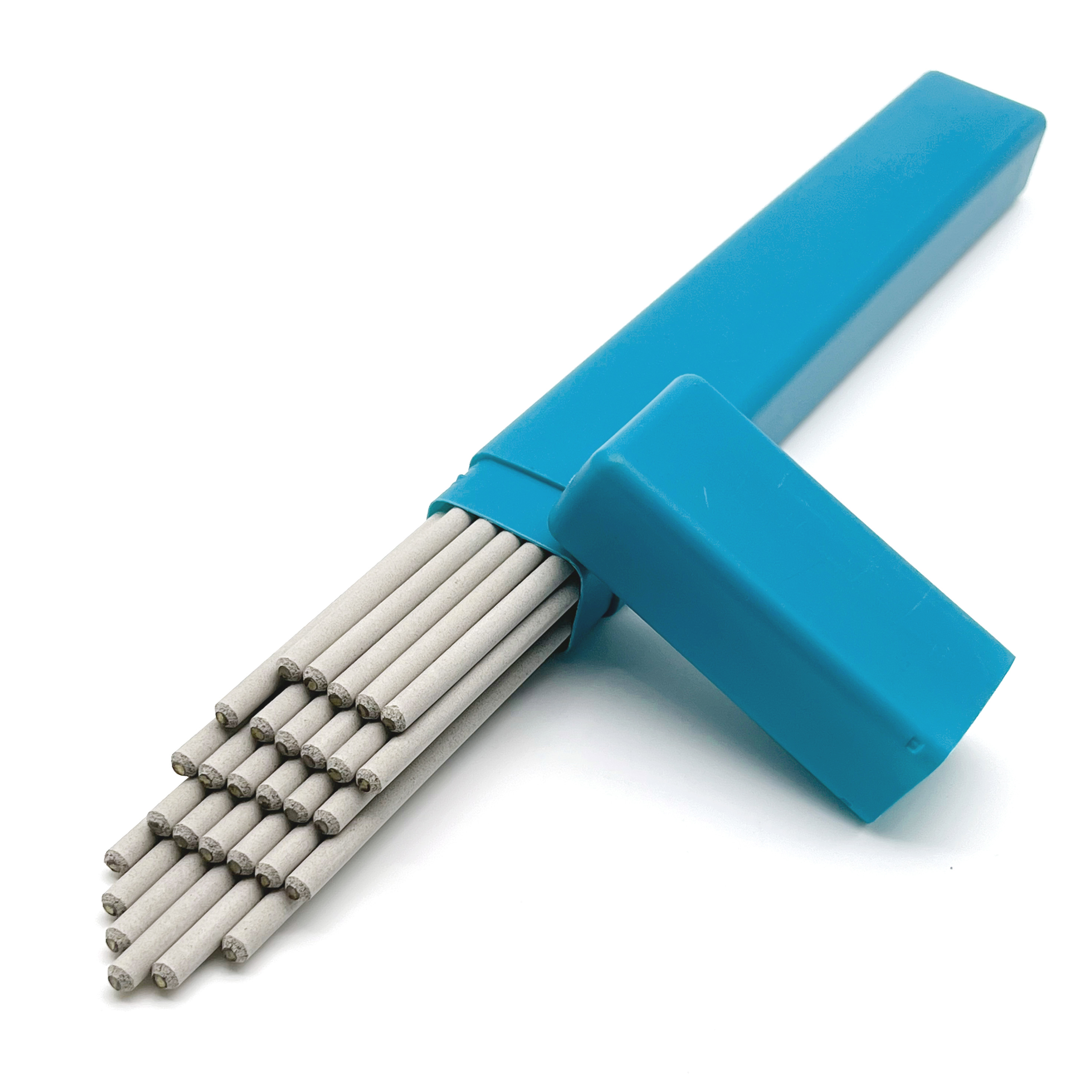

TSANANGURO:

PA-8016-B8 ishoma hydrogen electrode iyo weld simbi ine 9% Cr-1% Mo.Yakagadzirirwa kukwirisa tembiricha simbi uye simbi kune inopisa hydrogen masevhisi, kunyanya mu petrochemical indasitiri.Iyo electrode inogona kutenderwa kune yayo yakanyanya kusimba simba, kusimba kwakanaka uye kukuru kupisa kupisa.

MAZANO PAKUSHANDISA:

1. Dry electrodes pa 350-400 ° C kweinenge awa imwe isati yashandiswa uye chengetedza ma electrodes pa 100-150 ° C mushure mekuomesa nekucherechedza kuti urege kubva kune unyoro.

2. Adopt back step method kana kurova arc pane diki simbi ndiro yakagadzirirwa chinangwa ichi kudzivirira blowholes paarc kutanga.

3. Chengeta arc ipfupi sezvinobvira.

4. Preheat pa 100-150 ° C.Tembiricha ichashandiswa inosiyana zvichienderana nekukora kweplate uye rudzi rwesimbi ichaiswa weld.

5. Chenjerera kuti usapfuure kwakakodzera kupisa-inopinza nekuti yakawandisa kupisa-inopinza kunokonzera kuderera kwemaitiro emhedzisiro uye goho simba re weld simbi.

IV.TYPICAL CHEMICAL COMPOSITION OF WELD METAL (%):

| C | Si | Mn | Cr | Mo |

| 0.06 | 0.42 | 0.68 | 9.38 | 1.05 |

V. TYPICAL MECHANICAL PROPERTIES OF WELD METAL:

| Tensile Simba N/mm2(Ksi) | Goho Point N/mm2 (Ksi) | Elongation % | PWHT |

| 705 (102) | 560 (81) | 24 | 740°C x 1 awa |

VI.WEDDING POSITIONS: ALL POSITIONS

VII.SIZE UYE ZVINOKURUKURWA ZVINO RANGE (AC/DC+):

| Dhayamita (mm) | 2.5 | 3.2 | 4.0 | 5.0 | |

| Urefu (mm) | 350 | 350 | 400 | 400 | |

| Ampere | Flat | 55 - 85 | 90 - 130 | 130 - 180 | 180 - 240 |

| V uye OH | 50 - 80 | 80 - 115 | 110 - 170 | 150 - 200 |