ERNiFe-CI inoshandiswa kugadzira simbi yakakandwa.Iyi simbi yekuzadza inoshandiswa zvakanyanya kufukidza simbi yakaumbwa.Inoshandiswawo kugadzirisa ma castings.Preheat uye interpass tembiricha ye175ºC (350ºF) shoma inokurudzirwa panguva yewelding, pasina iyo weld uye kupisa kwakakanganiswa nzvimbo zvinogona kuita makatsemuka.

Ni 55 (kirasi yeAWS haina kutaurwa) inonzi 55% Nickel waya.Iyo yakaderera Nickel yemukati inoita kuti alloy iyi iwedzere mari kupfuura Ni 99. Weld deposits inowanzoita muchina, asi pasi pemamiriro epamusoro admixture, welds inogona kuoma uye yakaoma kumuchina.Inowanzoshandiswa pakugadzirisa makanda ane zvikamu zvinorema kana zvakakora.Sezvichienzaniswa neNi 99, welds akagadzirwa ne55 Ni ane simba uye akawedzera ductile, uye anoshivirira phosphorus mukukanda.Iyo ine zvakare yakaderera coefficient yekuwedzera kupfuura Ni 99, zvichikonzera kushomeka kwemutsara wekutsemuka.

CHEMICAL COMPOSITION:

| NickelNi45.0-60.0% | IronFebalance | SiliconSimax 4.0% | ManganeseMn2.5% | MhanguraCu2.5% | CarbonCmax 2.0% | AluminiumAlmax 1.0% |

MACHINICAL PROPERTIES:

| Tensile simba Rm (MPa) | Goho simba Rp0.2 (MPa) | Elongation A % |

| min.393-579 (57-84 psi) | 296-434 (40-64 psi) | 6-13 |

MAFOMU ZVINHU:

| Product | Diameter, mm | Urefu, mm |

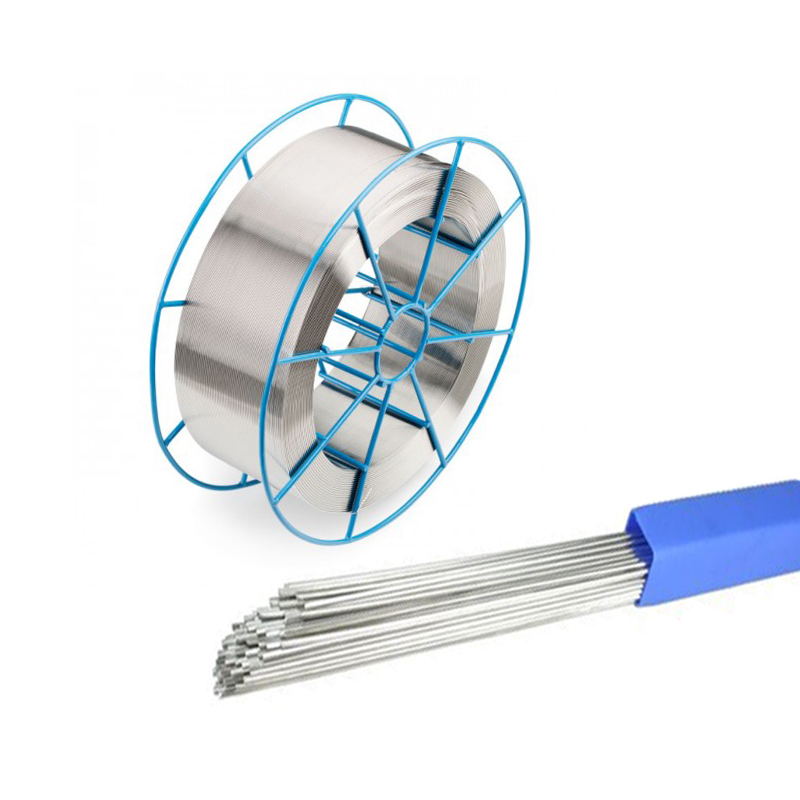

| Waya yeMIG/GMAW welding | 0.8, 1.0, 1.2, 1.6, 2.0, 2.4, 2.5, 3.2 | - |

| Tsvimbo dzeTIG/GTAW welding | 2.0, 2.5, 3.2, 4.0, 5.0 | 915 - 1000 |

| Waya yeSAW welding | 2.0, 2.4, 3.2, 4.0, 5.0 | - |

| Electrode core wire | 2.0, 2.5, 3.20, 3.25, 4.0, 5.0 | 250, 300, 350, 400, 450, 500 |

Binary Nickel-Iron (Ni-Fe) uye Ni based complex welding alloys anopihwa muwelding tsvimbo uye waya muhurefu hwakaenzana kana kureba kusvika kune chikumbiro chevatengi.Kune akajairwa sevhisi mamiriro, iwo maumbirwo emakemikari anowanikwa mune dzakasiyana-siyana dzeNi zvirimo zvinoenderana neakawanda eAmerican neEuropean zviyero.