Aruminiyamu yeERCuAl-A1 BhronziWaya yekunamiraisimbi isina simbi, aruminiyamu bronze alloy inowanikwa muwaya yakasanganiswa uye simbi ine 36” isina chinhu inoshandiswa pamwe chete nekugadzira gas metal-arc uye gas tungsten-arc welding.

Aruminiyamu yeERCuAl-A1 BhronziWaya yekunamiraMadhaidhi anoshandiswa zvakanyanya kufukidza mabheyaringi nenzvimbo dzisingapfeki dzinoda kuomarara kweinenge 125 BHN uye kudzivirira ngura kunyanya kubva mumvura ine munyu, munyu wesimbi, uye maasidhi akawanda anowanzoshandiswa muhuwandu hwakasiyana uye tembiricha. Musanganiswa uyu haukurudzirwi kujoina sezvo dhaidhi yacho isinganyanyi kupisa.

Waya yeERCuAl-A1 Aluminium Bronze Welding Waya yeAluminium Bronze Welding Mashandisirwo ewaya anosanganisira machubhu, zvigaro zvemavharuvhu, zvikorekedzo zvepickling, maimpeller, makemikari, uye ma pulp mills.

Waya yesimbi yeERCUAL-A1 Aluminum Bronze Welding Properties yemuviri neyemakanika

| Zvinhu Zvine Simba-Kupisa | 1030℃ |

| Kuwanda kwevanhu | 7.7kg/dm³ |

| Kureba | 40-45% |

| Zvinwiwa-Kupisa | 1040℃ |

| Simba reKusimba | 380-450N/mm² |

| Kuomarara kwaBrinell | 100HB |

Kurongedza waya dzesimbi dzeERCUAL-A1 Aluminum Bronze

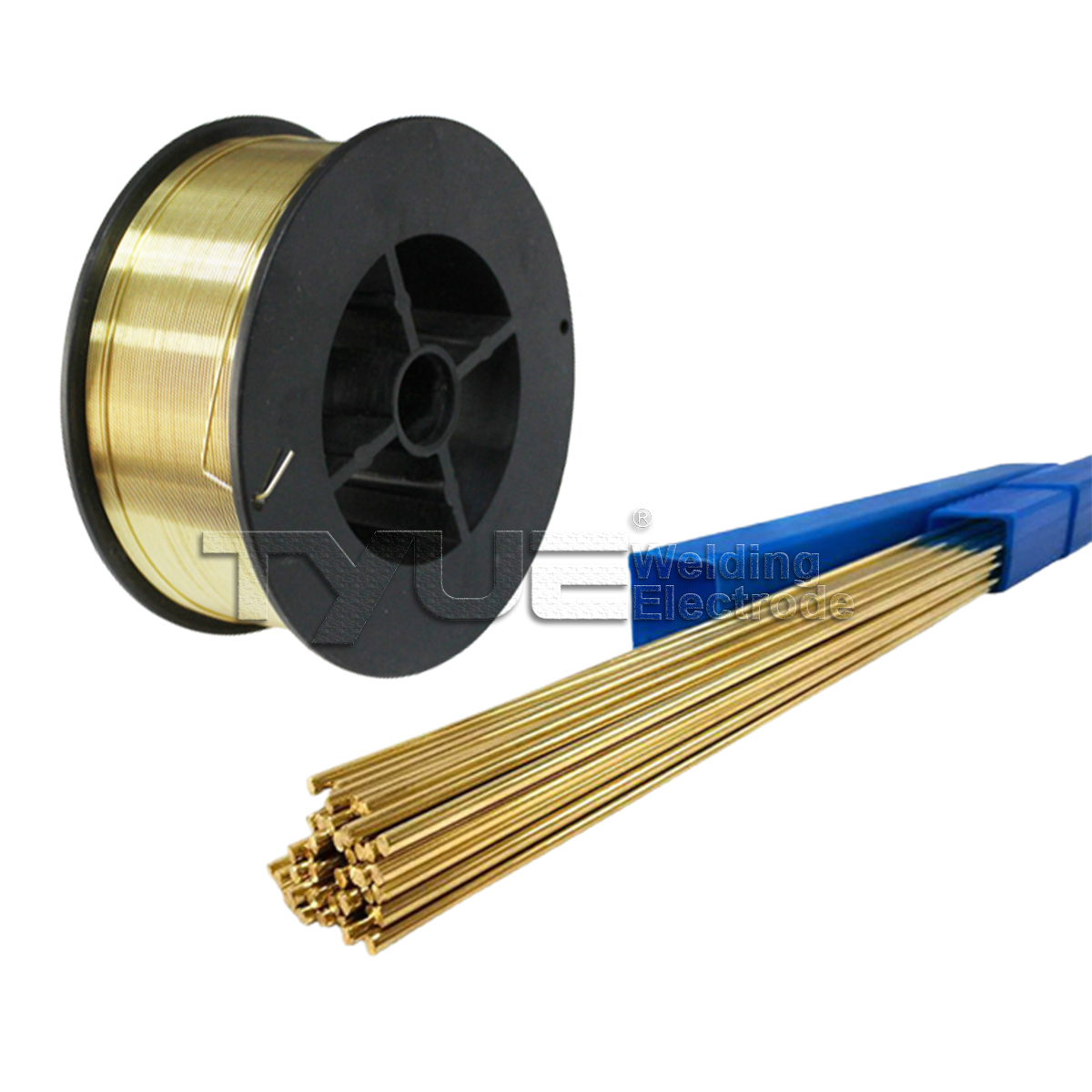

| MIG | Dhayamita | 0.8 – 2.0mm | Kurongedza | D100mm D200mm D300mm | Huremu | 1kg/5kg/12.5kg/13.6kg/15kg |

| 0.030″-5/64″ | 2lb/10lb/27lb/ 30lb/33lb | |||||

| TIG | Dhayamita | 1.6 - 6.4mm | Kureba | 457mm / 914mm | Kurongedza | 5kg/bhokisi 25kg/bhokisi 10kg/purasitiki pasuru |

| 1/16″ – 1/4″ | 18″ / 36″ | 10lb/bhokisi 50lb/bhokisi 10kg/purasitiki |

Ndapota cherechedzai: Zvigadzirwa zvemapuranga zve500lb zvinowanikwa kana zvakumbirwa.

Waya yesimbi yeERCUAL-A1 Aluminum Bronze Welding (yakasanganiswa nemakemikari)

| Zvakajairika | ISO24373 | GB/T9460 | GB/T9460 | BS EN14640 | AWS A5.7 | DIN 1733 |

| Kirasi | Cu6100 | SCu6100 | SCu6100A | Cu6100 | C61000 | 2.0921 |

| chiwanikwa | CuAl7 | CuAl7 | CuAl8 | CuAl8 | ERCuAl-A1 | SG-CuAl8 |

| Cu | bal. | bal. | bal. | bal. | bal. | bal. |

| Al | 6.0-8.5 | 6.0-8.5 | 7.0-9.0 | 6.0-9.5 | 6.0-8.5 | 7.5-9.5 |

| Fe | – | – | 0.5 yepamusoro | 0.5 | – | 0.5 yepamusoro |

| Mn | 0.5 | 0.5 yepamusoro | 0.5 yepamusoro | 0.5 | 0.5 | 1.0 yepamusoro |

| Ni | – | – | 0.5 yepamusoro | 0.8 | – | 0.8 yepamusoro |

| P | – | – | – | – | – | – |

| Pb | 0.02 | – | 0.02 yepamusoro | 0.02 | 0.02 | 0.02 yepamusoro |

| Si | 0.2 | 0.1 yepamusoro | 0.2 yepamusoro | 0.2 | 0.1 | 0.2 yepamusoro |

| Sn | – | – | 0.1 yepamusoro | – | – | – |

| Zn | 0.2 | 0.2 yepamusoro | 0.2 yepamusoro | 0.2 | 0.2 | 0.2 yepamusoro |

| zvimwe | 0.4 | 0.5 yepamusoro | 0.2 yepamusoro | 0.4 | 0.5 | 0.4 yepamusoro |

Wenzhou Tianyu Electronic Co., Ltd. yakavambwa muna 2000. Tave tichigadzira maerekitironi ekuwelda, tsvimbo dzekuwelda, uye zvinhu zvinoshandiswa pakuwelda kweanopfuura makore makumi maviri.

Zvigadzirwa zvedu zvikuru zvinosanganisira maelectrode esimbi isina ngura, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni & cobalt, mawaya esimbi yekabhoni & low alloy, waya dzesimbi yekabhoni & low alloy, waya dzesimbi yekabhoni, waya dzesimbi yekabhoni, waya dzakavharirwa negesi, waya dzesimbi yekabhoni ...