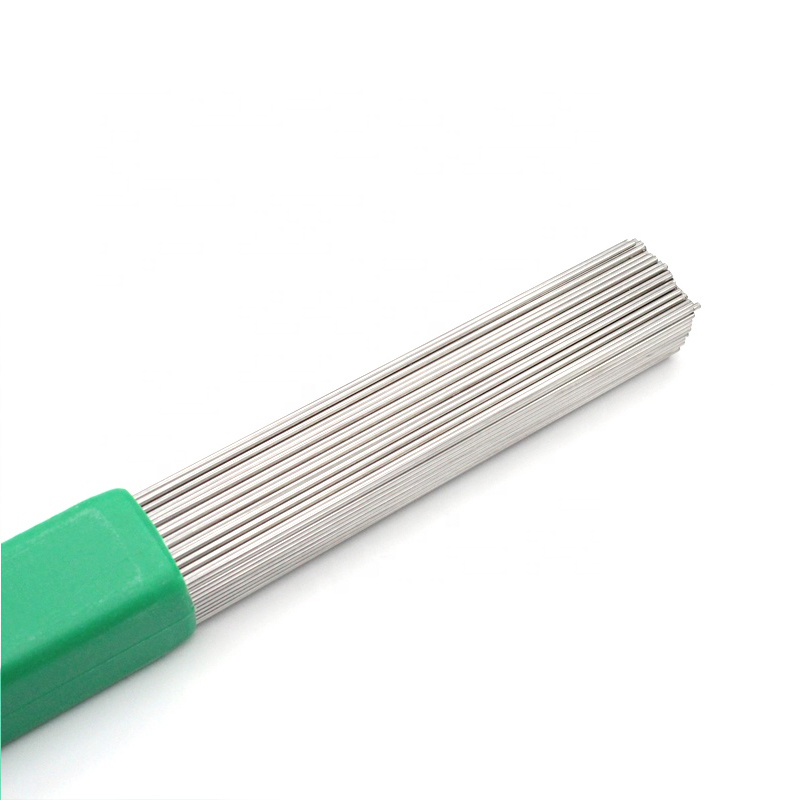

ER4043 iwaya yekubatanidza yearuminiyamu inoshandiswa zvakanyanya. Ndiyo imwe yearuminiyamu yekare uye inonyanya kushandiswa pakushongedza nekushongedza. Iyi aruminiyamu ine silicon additives, izvo zvinoita kuti dziva rekushongedza riwedzere kunyorova uye rinoita kuti rive nyore kupwanyika. Kupenya kwayo kwekubatanidza kunoita kuti ive sarudzo yakakurumbira yearuminiyamu. ER4043 inogona kushandiswa kushongedza mhando dzakasiyana dzearuminiyamu.

Mashandisirwo Akajairika: waya yekuzadza welding; waya yespray uye simbi inodzima moto

| Kirasi yeAWS: ER4043 | Chitupa: AWS A5.10/ A5.10M:1999 |

| Chiwanikwa: ER4043 | AWS/ASME SFA A5.10 |

| Nzvimbo Yekushongedza: F, V, OH, H | Zvazvino: DCEP-GMAW AC-GTAW |

Zvimiro Zvakajairika (sezvakasungirirwa)

| Kufambisa: | 42% IACS (-12) |

| Simba reKusimba, kpsi: | 29 |

| Ruvara: | Gireyi |

| Nzvimbo Yokunyunguduka | 1170⁰F | Kusimba | 1065⁰F | Kuwanda kwevanhu | 0.097 lbs/cu Mukati. |

Kemikari yeWaya Yakajairika zvichienderana neAWS A5.10 (hunhu humwe chete ndihwo hwakanyanya)

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Zvimwe | Al | ||||||

| 4.5-6.0 | 0.8 | 0.30 | 0.05 | 0.05 | 0.10 | 0.20 | 0.15 | Zvasara | ||||||

| Zvakajairika Zvekushongedza Zvimiro | ||||||||||||||

| Dhayamita | Maitiro | Volt | Maampisi | GESI | ||||||||||

| in | (mm) | |||||||||||||

| .030 | (.8) | GMAW | 15-24 | 60-175 | Argon (cfh) | |||||||||

| .035 | (.9) | GMAW | 15-27 | 70-185 | Argon (cfh) | |||||||||

| 3/64” | (1.2) | GMAW | 20-29 | 125-260 | Argon (cfh) | |||||||||

| 1/16” | (1.6) | GMAW | 24-30 | 170-300 | Argon (cfh) | |||||||||

| 3/32” | (2.4) | GMAW | 26-31 | 275-400 | Argon (cfh) | |||||||||

| Dhayamita | Maitiro | Volt | Maampisi | GESI | ||||||||||

| in | (mm) | |||||||||||||

| 1/16” | (1.6) | GTAW | 15 | 60-80 | Argon (cfh) | |||||||||

| 3/32” | (2.4) | GTAW | 15 | 125-160 | Argon (cfh) | |||||||||

| 1/8” | (3.2) | GTAW | 15 | 190-220 | Argon (cfh) | |||||||||

| 5/32” | (4.0) | GTAW | 15 | 200-300 | Argon (cfh) | |||||||||

| 3/16” | (4.8) | GTAW | 15-20 | 330-380 | Argon (cfh) | |||||||||

Wenzhou Tianyu Electronic Co., Ltd. yakavambwa muna 2000. Tave tichigadzira maerekitironi ekuwelda, tsvimbo dzekuwelda, uye zvinhu zvinoshandiswa pakuwelda kweanopfuura makore makumi maviri.

Zvigadzirwa zvedu zvikuru zvinosanganisira maelectrode esimbi isina ngura, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni, maelectrode esimbi yekabhoni & cobalt, mawaya esimbi yekabhoni & low alloy, waya dzesimbi yekabhoni & low alloy, waya dzesimbi yekabhoni, waya dzesimbi yekabhoni, waya dzakavharirwa negesi, waya dzesimbi yekabhoni ...