| Simbi giredhi mhando | Mold steel: |

| Standard |

|

| Zvinyorwa zvekugadzira | Simbi ndiro,Sheet, Coil,Flat bar,Round bar,Strip steel,waya,Ese marudzi emafogi. |

| Mchining | Kutendeuka Kugaya Kukuya Kuchera gomba rakadzika: kureba max 9.8 metres. |

| Range yebasa | Round bar simbi: 1mm kusvika 2000mm Square-chimiro simbi: 10mm kusvika 1000mm simbi Plate/sheet:0.08mm kusvika 800mm Upamhi: 10mm kusvika 1500mm Lenth: Tinogona kupa chero lenth zvichienderana nezvinodiwa nemutengi. Kugadzira: Shafts ane flanks / pombi / machubhu / slugs / donuts / cubes / mamwe maumbirwo Tubings: OD: φ4-410 mm, nemadziro ukobvu kubva pa1-35 mm. |

| Kurapa kwekupisa | Normalizing,Annealing,Kupisa,Kudzima,Kuomesa uye kudzikama,Kurunga,Kuomesera kwepasi,Carburizing |

AWS E10015-D2 CHEMICAL COMPOSITION UYE MECHANICAL PROPERTIESL:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Zvimwe |

MACHINICAL PROPERTIES:

| Properties | Conditions | ||

| T (°C) | Kurapa | ||

| Density (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Poisson's Ratio | 0.27-0.30 | 25 |

|

| Elastic Modulus (GPa) | 190-210 | 25 |

|

| Tensile Strength (Mpa) | 1158 | 25 | mafuta akadzimwa, akacheneswa zviyo, akapisa pa425 ° C |

| Goho Simba (Mpa) | 1034 | ||

| Elongation (%) | 15 | ||

| Kuderedza Nzvimbo (%) | 53 | ||

| Kuoma (HB) | 335 | 25 | mafuta akadzimwa, akacheneswa zviyo, akapisa pa425 ° C |

| Properties | Conditions | ||

| T (°C) | Kurapa | ||

| Thermal Conductivity (W/mK) | 42.7 | 100 | |

| Chaicho Kupisa (J/kg-K) | 477 | 50-100 | |

ZVINHU ZVINHU:

| Quantity | Value | Unit |

| Kuwedzera kupisa | 16 - 17 | e-6/K |

| Thermal conductivity | 16-16 | W/mK |

| Kupisa chaiko | 500 - 500 | J/kg.K |

| Kunyunguduka tembiricha | 1370 - 1400 | °C |

| Kupisa kwebasa | 0 - 500 | °C |

| Density | 8000 - 8000 | kg/m3 |

| Resistivity | 0.7 - 0.7 | Ohm.mm2/m |

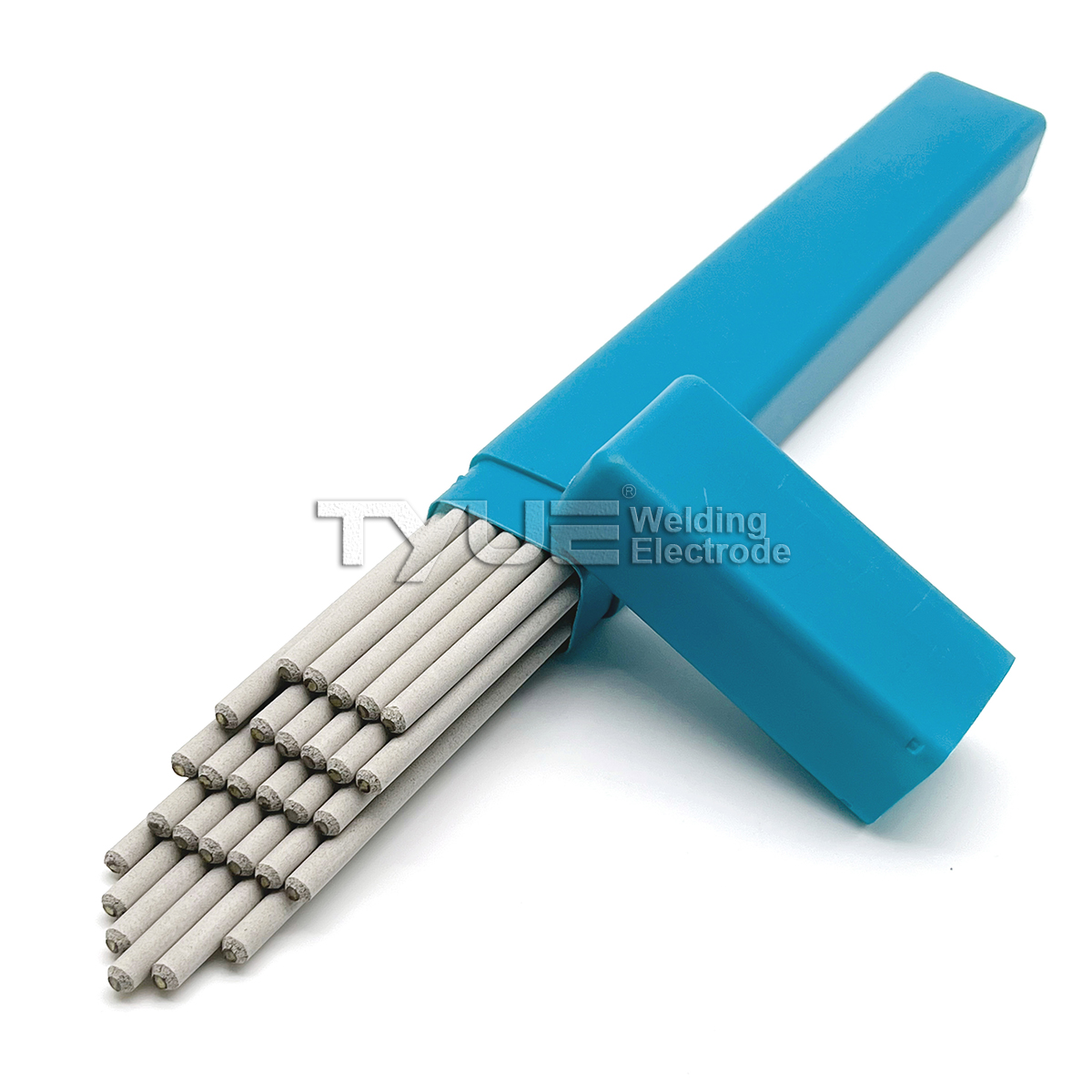

E7015-G Yakaderera Hydrogen Sodium Coating Welding Electrodes

DESCRIPTION:

Iyo yakaderera tembiricha yesimbi yewelding tsvimbo ine yakaderera sodium hydrogen coating ine nickel.Yakazara chinzvimbo welding inogona kuitwa nedc reverse yekubatanidza.Mu -80°C weld simbi ichine kunaka kusimba.

SHANDISA:

Welded -80 ° C kushanda 1.5Ni simbi chimiro.

DEPOSITED METAL CHEMICAL COMPOSITION:

| C | Mn | Si | Ni | S | P | |

| Standard | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Test | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

DEPOSITED METAL MECHANICAL PERFORMANCE:

| Tensile Simba Rm (MPa) | Yield Strength Rel (MPa) | Elongation A (%) | -80°C Impact Value Akv (J) | |

| Standard | ≥490 | ≥390 | ≥22 | ≥27 |

| Test | 530 | 445 | 30 | 100 |

REFERENTIAL CURRENT (DC+):

| Dhayamita (mm) | 3.2 | 4.0 | 5.0 | |

| Urefu (mm) | 350 | 400 | 400 | |

| Zvazvino (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Maererano neGB E8515-G Inoenderana neAWS E12015-G |

Nhanganyaya: E12015-G imhando yepasi-alloy yakakwirira simba simbi electrode ine yakaderera-hydrogen natrium mhando coating.DCRP (Direct Current Reversed Polarity).Zvese-nzvimbo welding.

Zvishandiso: Zvinoshandiswa kukwenenzvera low-alloy yakakwirira simba zvivakwa zvesimbi zvine simba rekusimba rinosvika 830MPa.

Kemikari Inoumbwa yeDeposited Metal (%)

| Kuumbwa Kwemakemikari | C | Mn | Si | S | P | Mo |

| Guarantee Value | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| General Result | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Mechanical Properties yeDeposited Metal

| Test Item | Rm(MPa) | ReL kanaRp0.2(Mpa) | A(%) | KV2(J) |

| Guarantee Value | ≥830 | ≥740 | ≥12 | —(tembiricha yakajairika) |

| General Result | 860~950 | ≥750 | 12-20 | ≥27 |

Diffusible Hydrogen Content muDeposited Metal: ≤5.0ml/100g(Chromatography)

X-ray Radiographic Kuongorora: ⅠDegree

MAZANO:

1.Ma electrodes anofanira kubikwa pasi pe 350-400 ℃ kweawa imwe isati yasveta, isa muvharo yekudzivirira uye inoshandiswa nokukurumidza pavanenge vachidiwa.

2.Mavara ari pa weld se ngura anofanirwa kubviswa, uye weld inofanira kupiswa kusvika pa200 ℃.

3.Weld inogona kuderedzwa pasi pe600-650 ℃ mushure mekugadzirisa kuitira kubvisa kushushikana kwemukati.