| Rudzi rwesimbi yegiredhi | Simbi yeforoma: |

| Zvakajairika |

|

| Zvimiro zvekugadzira | Ndiro yesimbi, Sheet, Coil, Flat bar, Round bar, Strip simbi, waya, Mhando dzese dzeforgings. |

| Kugadzira | Kutendeuka Kugaya Kukuya Kuboora makomba akadzika: kureba kwakanyanya 9.8 metres. |

| Mhando yebasa | Simbi yebhawa yakatenderera: 1mm kusvika 2000mm Simbi ine chimiro chesikweya: 10mm kusvika 1000mm Plate/pepa resimbi: 0.08mm kusvika 800mm Upamhi: 10mm kusvika 1500mm Lenth: Tinogona kupa chero lenth zvichienderana nezvinodiwa nemutengi. Kugadzira: Migove ine mativi/mapaipi/machubhu/slugs/madonati/macubes/mamwe maumbirwo Machubhu: OD: φ4-410 mm, ukobvu hwemadziro hunobva pa1-35 mm. |

| Kurapa kupisa | Kugadzirisa, Kuderedza, Kudzimisa, Kuomesa uye Kugadzirisa, Zvinonhuwira, Kuomesa pamusoro, Kuomesa Carburizing |

AWS E10015-D2 KUUMBIKA KWEMAKEMIKIRI UYE ZVINHU ZVEMAKANIKI:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Zvimwe |

ZVINHU ZVEMAKANIKISI:

| Zvivakwa | Mamiriro ezvinhu | ||

| T (°C) | Kurapa | ||

| Kuwanda (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Chiyero chaPoisson | 0.27-0.30 | 25 |

|

| Modulus yeElastic (GPa) | 190-210 | 25 |

|

| Simba reKusimba (Mpa) | 1158 | 25 | mafuta akadzima, akacheneswa zvakanaka, akanyoroveswa pa425°C |

| Simba reGoho (Mpa) | 1034 | ||

| Kureba (%) | 15 | ||

| Kuderedzwa kweNzvimbo (%) | 53 | ||

| Kuoma (HB) | 335 | 25 | mafuta akadzima, akacheneswa zvakanaka, akanyoroveswa pa425°C |

| Zvivakwa | Mamiriro ezvinhu | ||

| T (°C) | Kurapa | ||

| Kufambisa kwekupisa (W/mK) | 42.7 | 100 | |

| Kupisa Kwakasiyana (J/kg-K) | 477 | 50-100 | |

ZVINHU ZVEMUNYIKA:

| Huwandu | Kukosha | Chikamu |

| Kuwedzera kwekupisa | 16 - 17 | e-6/K |

| Kufambisa kwekupisa | 16 - 16 | W/mK |

| Kupisa kwakananga | 500 - 500 | J/kg.K |

| Kupisa kwekunyunguduka | 1370 - 1400 | °C |

| Tembiricha yebasa | 0 - 500 | °C |

| Kuwanda kwevanhu | 8000 - 8000 | kg/m3 |

| Kuramba | 0.7 - 0.7 | Ohm.mm2/m |

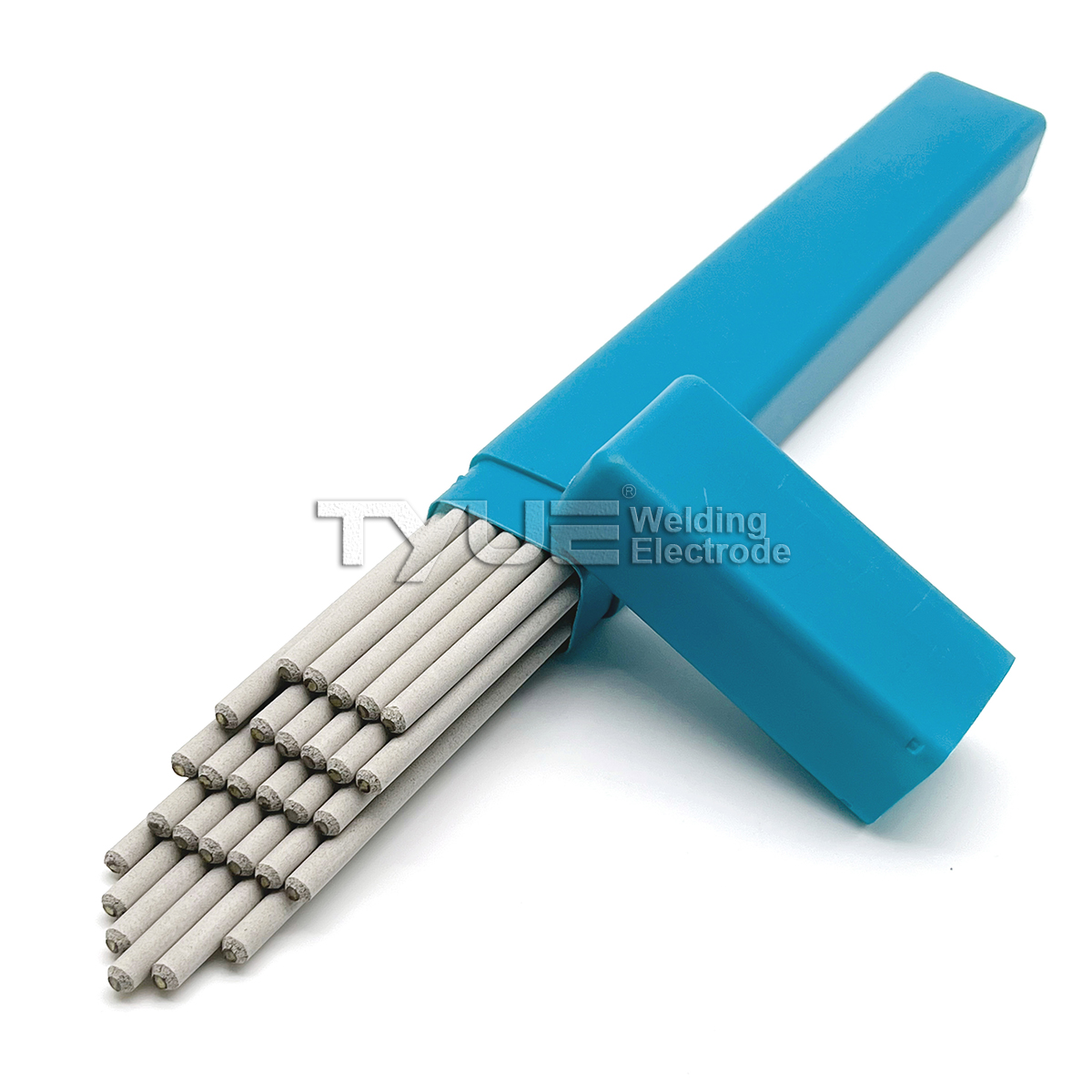

E7015-G Low Hydrogen Sodium Coating Welding Electrodes

TSANANGURO:

Isimbi inonamira pakupisa kwakaderera ine sodium hydrogen coating shoma ine nickel. Kunamira pachigaro chakazara kunogona kuitwa nekubatanidza ne dc reverse. Simbi inonamira pa -80°C ichiri yakasimba.

MASHANDISIRO:

Yakasungirirwa -80°C inoshanda nesimbi ye1.5Ni.

ZVINHU ZVEMASTER AKACHENGETEDZWA:

| C | Mn | Si | Ni | S | P | |

| Zvakajairika | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Bvunzo | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

KUSHANDA KWEMAKANIKISI YESIMBIRI YAKACHENGETEDZWA:

| Simba reKusimba (MPa) | Simba Rekubereka (MPa) | Kureba A (%) | -80°C Kukosha Kwemhedzisiro Akv (J) | |

| Zvakajairika | ≥490 | ≥390 | ≥22 | ≥27 |

| Bvunzo | 530 | 445 | 30 | 100 |

REFERENTIAL current (DC+):

| Dhayamita (mm) | 3.2 | 4.0 | 5.0 | |

| Kureba (mm) | 350 | 400 | 400 | |

| Ikozvino (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Zvinoenderana neGB E8515-G Inoenderana neAWS E12015-G |

Nhanganyaya: E12015-G rudzi rweelectrode yesimbi ine simba rakaderera ine hydrogen natrium coating. DCRP (Direct Current Reversed Polarity). Kushongedza kwenzvimbo dzese.

Mashandisirwo: Inoshandiswa pakunamira simbi ine simba rakawanda ine simba rekudhonza rinosvika 830MPa.

Kuumbwa kweMakemikari eSimbi Yakachengetwa (%)

| Kuumbwa kweMakemikari | C | Mn | Si | S | P | Mo |

| Kukosha kweVimbiso | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| Mhedzisiro Yese | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Zvimiro zveMechanical zveSimbi Yakachengetwa

| Chinhu Chekuyedza | Rm(MPa) | ReL kanaRp0.2(Mpa) | A(%) | KV2(J) |

| Kukosha kweVimbiso | ≥830 | ≥740 | ≥12 | —(tembiricha yakajairika) |

| Mhedzisiro Yese | 860~950 | ≥750 | 12~20 | ≥27 |

Hunhu hweHydrogen Hunopararira muSimbi Yakachengetwa: ≤5.0ml/100g (Chromatography)

Kuongororwa kweX-ray Radiographic: ⅠDegree

MIRAYIRO:

1. Maelectrode anofanira kubikwa pasi pe350-400℃ kweawa imwe chete asati abatanidza, oiswa mugaba rekudzivirira kupisa uye obva angoashandisa nekukurumidza kana achidikanwa.

2. Mavara ari paweld akaita sengura anofanira kubviswa, uye weld inofanira kupisa kusvika pa200℃.

3. Weld inogona kudzikiswa pasi pe600-650℃ mushure mekuwelda kuitira kubvisa kushushikana kwemukati.