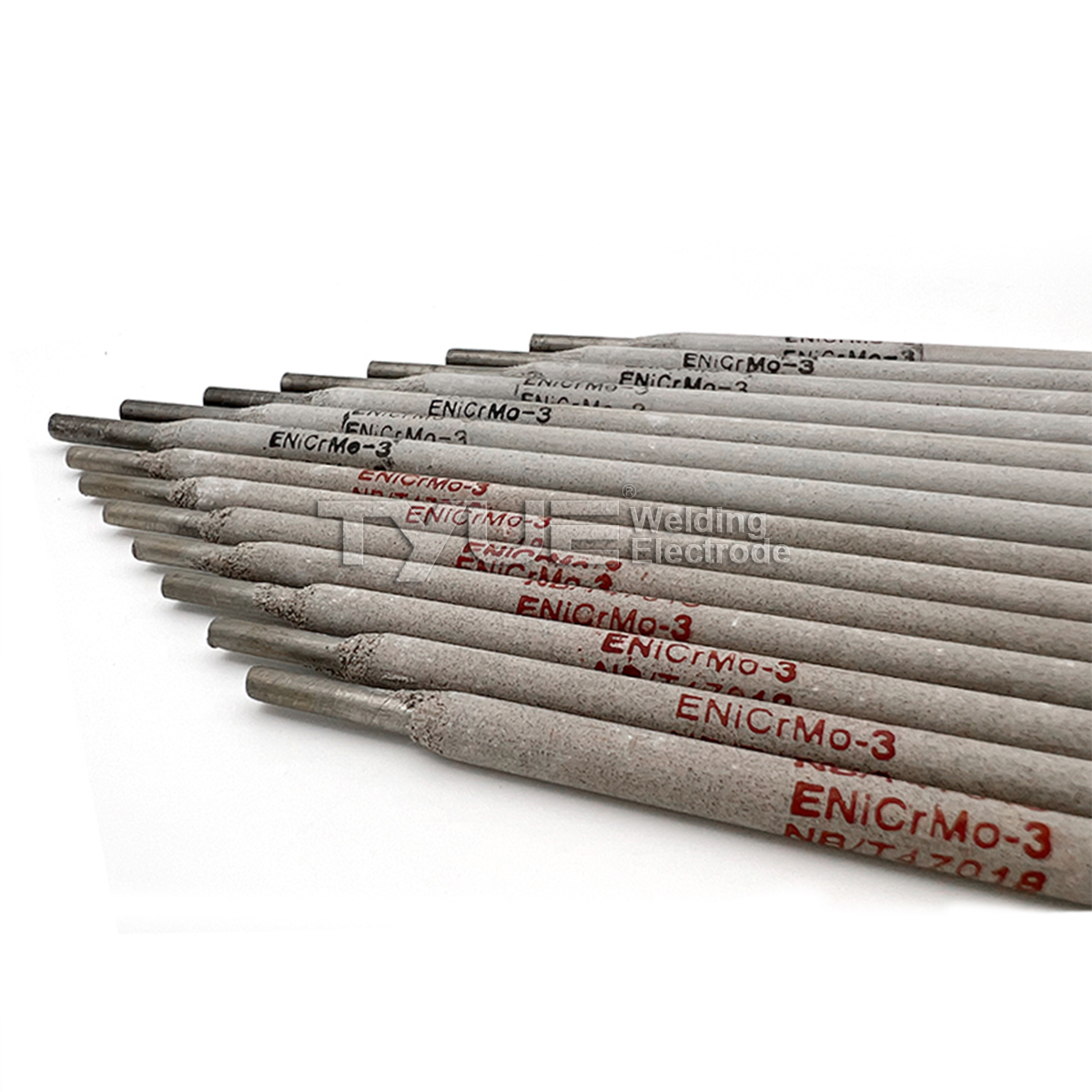

Nickel uye Nickel AlloyKushongedzaElectrode

Ni327-3

GB/T ENi6625

Tsananguro: Ni327 -3 ielectrode yakavakirwa panickel ine hydrogen sodium shoma. Shandisa DCEP (electrode yakananga yemagetsi)yakanaka). Simbi yakachengetwa ine ngura yakanaka, yakasimba uye inodzivirira kutsemuka, uye ine simba rakawanda uye inodzivirira ngura zvakanyanya patembiricha yemumba uye tembiricha yakakwira.

Mashandisirwo: Inoshandiswa pakusanganisa nickel-chromium-molybdenum alloys, kunyanya pakusanganisa nekugadzira UNS N06625 alloys nedzimwe mhando dzesimbi uye nickel-chromium-molybdenum alloy composite steels, uye inogona kushandiswawo pakusanganisa Ni9% steel pasi pemamiriro ekupisa akaderera.

Kuumbwa kwemakemikari esimbi ye weld (%):

| C | Mn | Si | Cr | Ni | Mo |

| ≤0.10 | ≤2.0 | ≤0.8 | 20.0 ~ 23.0 | ≥55.0 | 8.0 ~ 10.0 |

| Fe | Cu | Nb + Ta | S | P | Zvimwe |

| ≤7.0 | ≤0.5 | 3.0 ~ 4.2 | ≤0.015 | ≤0.020 | ≤0.5 |

Hunhu hwesimbi ye weld:

| Chinhu chekuyedza | Simba rekusimba Mpa | Simba rekupa Mpa | Kureba % |

| Yakavimbiswa | ≥760 | ≥420 | ≥27 |

Inokurudzirwa yemagetsi:

| Dhayamita yetsvimbo (mm) | 2.5 | 3.2 | 4.0 |

| Welding current (A) | 50 ~ 70 | 80 ~ 100 | 110 ~ 150 |

Cherechedza:

- Electrode inofanira kubikwa kweawa imwe chete pa300℃ isati yashandiswa pakusanganisa. Edza kushandisa arc pfupi kusanganisa;

- Zvakakosha kuchenesa ngura, mafuta, mvura, uye tsvina pazvikamu zvekunamira usati wanamira.

3. Edza kushandisa simba diki pakusanganisa, kusanganisa tambo dzakawanda uye kusanganisa tambo dzakawanda.