Kusonwa kweTIG kwakatanga kugadzirwa muAmerica (USA) muna 1936, kunozivikanwa seArgon arc welding. TIG inobvumira majoini emhando yepamusoro kuti agadzirwe negasi risingashande rine mhedzisiro yakachena yekubatanidza. Iyi nzira yekubatanidza inzira yekubatanidza ine chinangwa chose maererano nezvinhu zvinoshandiswa, ukobvu hwemadziro, uye nzvimbo dzekubatanidza.

Zvakanakira nzira iyi yekuwelda simbi ndezvekuti haibudisi mvura yakawanda uye haina kusvibisa zvakawanda, ukuwo ichivimbisa kuti pachava ne weld joint yepamusoro-soro kana ikashandiswa nemazvo. Kudyara zvinhu zvinoshandiswa pakuwelda simbi pamwe chete nemagetsi hazvina kubatana, saka izvi zvinoita kuti TIG ikodzere kushandiswa pakuwelda root passes uye pakuwelda panzvimbo.

Zvisinei, TIG welding inoda welder yakadzidziswa zvakanaka kuti iishandise neunyanzvi uye ruzivo rwekushandisa voltage nema amperage nemazvo. Izvi zvinotsigira mhedzisiro yakachena uye yakanakisa yeTIG welding. Uye ndinofunga kuti izvi ndizvo zvinonyanya kukonzera matambudziko eTIG welding.

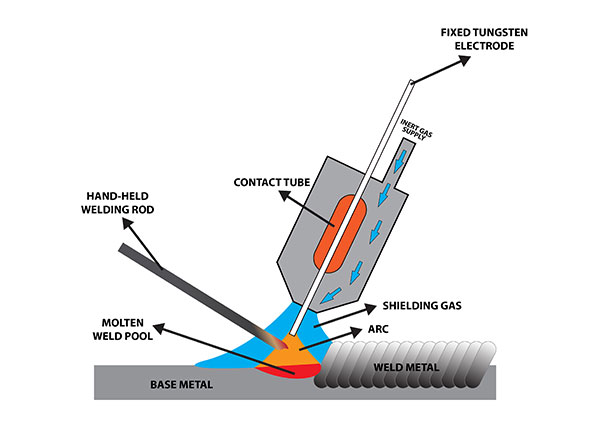

Sezvamunoona mumufananidzo iwoyo, mushure mekunge madzvanya switch yetochi, gasi rinotanga kuyerera. Uye kana muromo wetochi wabata pamusoro pesimbi, panoitika short circuit. Nekuda kwehuwandu hwemagetsi ari pamucheto wetochi, simbi inotanga kupwanyika panzvimbo yainosangana uye arc inobatidza, hongu, yakafukidzwa negasi rinodzivirira.

KUGADZIRA KUDIKIDZIKA KWEGASI/KUYERA KWEMAFUTA

Mwero wekuyerera kwegasi uri mu l/min uye zvinoenderana nehukuru hwedziva rekuweld, dhayamita ye electrode, dhayamita yemuromo wegasi, daro remuromo wesimbi, mafambiro emhepo akakomberedza uye rudzi rwegasi rinodzivirira.

Mutemo uri nyore ndewekuti marita mashanu kusvika gumi egasi rekudzivirira anofanira kuwedzerwa kuargon segasi rekudzivirira uye kune dhayamita dze electrode dze tungsten dzinoshandiswa zvakanyanya, pamwero we 1 kusvika 4 mm paminiti.

NZVIMBO YETOCHI

Sekunge muMIG Welding, nzvimbo yetochi, kana uchishandisa nzira yeTIG Welding, inokoshawo zvikuru. Nzvimbo yetochi netsvimbo yeelectrode zvinokanganisa mhedzisiro dzakasiyana dzewelding.

Iyo Electrode pachayo inoshandiswawo pakushongedza simbi inoshandiswa panguva yekushongedza TIG. Zvishandiso zvekushongedza simbi zvinowanzo sarudzwa nenzira imwecheteyo nerudzi rwesimbi. Zvisinei, nekuda kwezvikonzero zvesimbi, zvakakosha kuti zvinoshandisa pakushongedza simbi zvisiyane nesimbi huru kana zvimwe zvinhu zvekusanganisa zvikashandiswa.

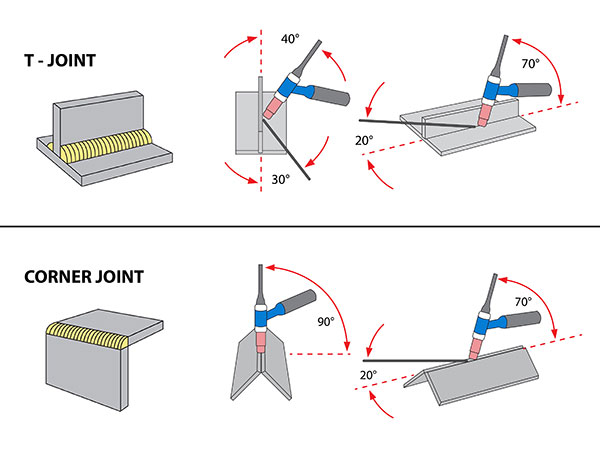

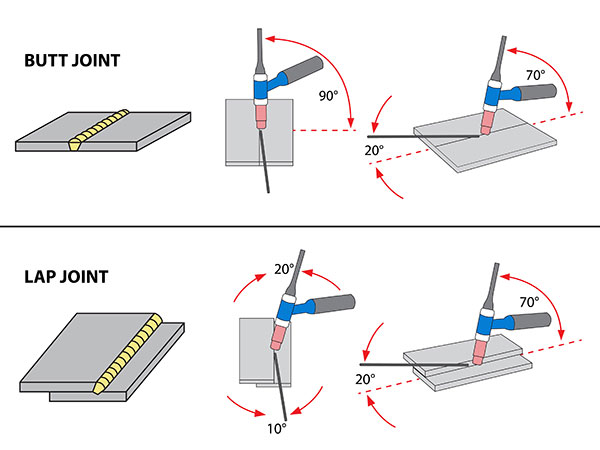

Kudzokera kunzvimbo yetochi. Unogona kuisa nzvimbo dzakasiyana dzetochi yeTIG netsvimbo yeelectrode uku uchibatanidza majoini esimbi akasiyana-siyana. Saka nzvimbo yetochi inoenderana nerudzi rwemajoini esimbi. Ndiri kureva kuti kune majoini mana esimbi ekutanga akadai se:

T- Joint

Joinhi yekona

Joint yeMatako

Joinhi yemakumbo

Unogona kushandisa mamwe ematochi aya pabasa raunoda kupedzisa. Uye kana ukajairana nematanho akasiyana-siyana ekubatanidza matoni esimbi, unogona kudzidza nezvematanho ekubatanidza matoni.

ZVIGADZIRWA ZVEKUWEDZERA

Pakusarudza maparamita ekuwelda, zvinofanira kucherechedzwa kuti magetsi chete ndiwo anoiswa pamuchina wekuwelda. Voltage inotarwa nehurefu hwe arc, iyo inochengetwa nemuchina wekuwelda.

Saka, kureba kwearc yakakura kunoda voltage yakakwira yearc. Kuwelda kwemagetsi kwe45 amperages pa mm yeukobvu hwesimbi kunoshandiswa sechiratidzo chemagetsi anokwana simbi yekuwelda kuti ipinde zvizere.

YAKATUMIRWA NA WENZHOU TIANYU ELECTRONIC CO., LTD.

Nguva yekutumira: Chikumi-12-2023